How can we help?

Convert Excess Planned Downtime to Unplanned

Overview

If a Planned Downtime, such as Setup, lasts too long it may be preferable to consider the excess time Unplanned Downtime instead. This tutorial will explain the process and provide the needed expressions to set up this configuration.

Tutorial

The first step is to create a new Unplanned Downtime that the excess Planned Downtime will be converted to.

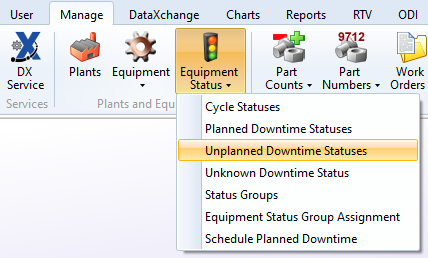

- Login to the DataXchange Windows Application and go to the Manage tab.

- Select Equipment Status → Unplanned Downtime Statuses.

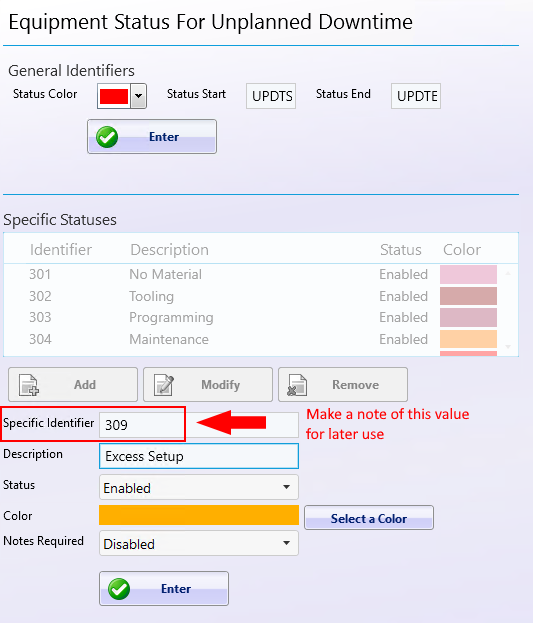

- Click Add to create a new Unplanned Downtime.

- Enter a Description (Name) for the status and select a Color to represent the status. Click Enter to save the Status.

Make a note of the status Specific Identifier as this is needed in the Expression.

- Go to Equipment Status → Planned Downtime Statuses and make a note of the Specific Identifier for the Planned Downtime that will be converted to this Unplanned Downtime after enough time has passed.

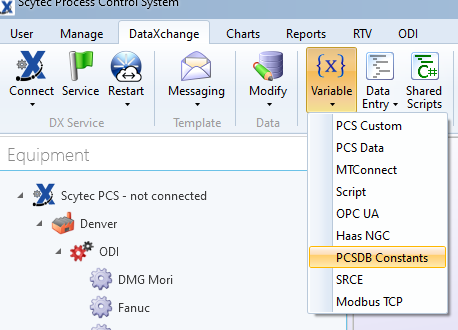

- Now, go to the DataXchange tab. Select Variable → PCSDB Constants.

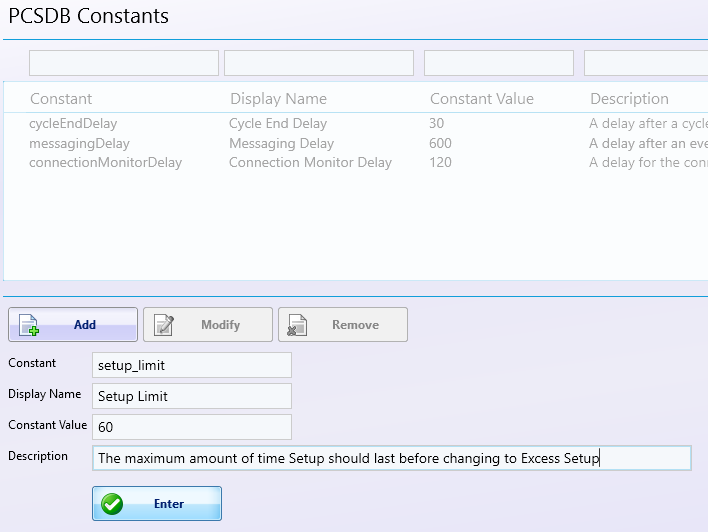

- Create a new constant and set the Constant Value to the amount of time to wait before the Downtime is considered excessive. This value is in Minutes. Make a note of the Constant field as this name will be needed to create the Expression.

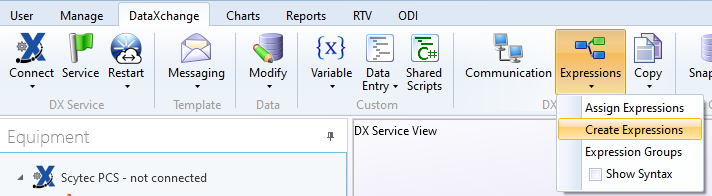

- Select Expressions → Create Expressions.

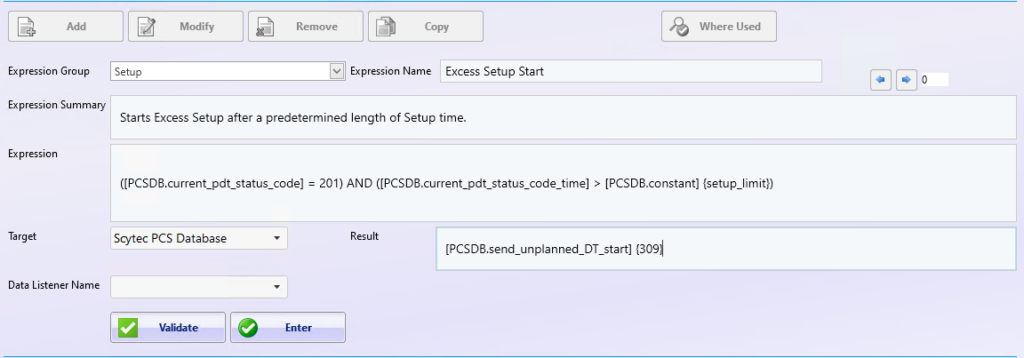

- Click Add to create a new Expression.

- Select an Expression Group then enter an Expression Name and Summary. Use the following as the Expression, replacing the Status Codes and Constant Name as needed:

([PCSDB.current_pdt_status_code] = 201) AND ([PCSDB.current_pdt_status_code_time] > [PCSDB.constant] {setup_limit})

Set the Target to Scytec PCS Database.

Result:

[PCSDB.send_unplanned_DT_start] {309}

Be sure to replace 309 with the Unplanned Downtime Status Code created earlier. Click Enter when finished.

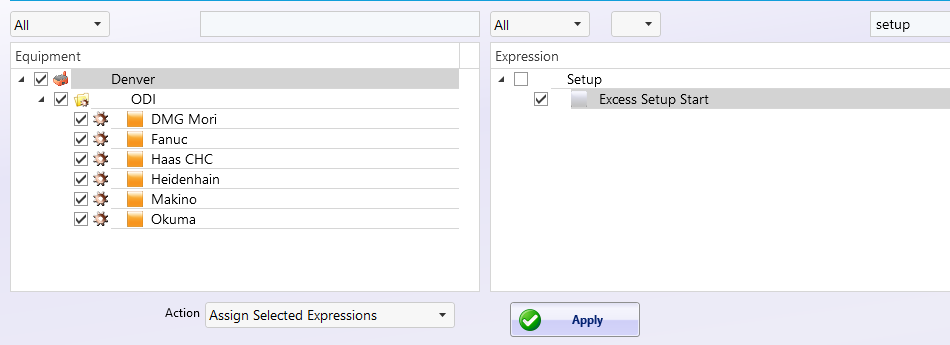

- The last step is to assign the expression to the applicable machines. Close the Expressions screen and go to Expressions → Assign Expressions.

- Select the Expression and the Equipment to which it will be added. Ensure Assign Selected Expressions is selected as the Action, and click Apply.

In some cases, the Setup status may be considered a “locked” status where it does not end when the Equipment is cycling. In this case the Excess Setup status probably should be a locked status as well. Instructions for locking statuses until they are ended manually can be found here.